|

Ningo goal sure machining co. ,ltd

|

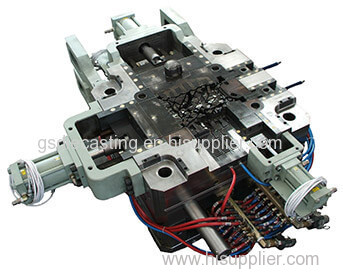

Custom Aluminum die cast mold service Aluminium Die Casting Manufacturers In China

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Custom Aluminum die cast mold service Aluminium Die Casting Manufacturers In China

Custom Aluminum die cast mold service Aluminium Die Casting Manufacturers In China Aluminum Casting Mold Making

3D and 2D products drawing from customer, the step of mould flow simulation is necessary. To find any potential defects during casting. For example, some parts have A surface and B surface request. Particularly for nickel finishing die casting parts. No any air porosity allowances, many of parts will need secondly machining. Have air bulb occur after machining. Some parts will have very strict tolerances in same axle. This time JSCAST CAE software will offer great solution.in fact all aluminum die casting molds manufactory designer need advanced CAE software to help their job, not only the experiences. DFM for customer confirm, the step of raw material quality checking is very important, particularly the mold core material checking. Now material of H13, SKD61, 8407, 1.2344, DH-31 widespread use in Ningbo die casting mold manufactory. We not only checking the checking the chemical composition and mechanical property. The material pure standard also very important for die casting tooling.

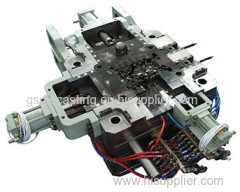

The injection speed and filling velocity control well when casting gate located in thick part

For excellent air venting, the parting line better located the end of casting system

Let air have time escape from mold cavity before moving die and fixed die closed

Good parting line design should think about how to reduce deburr cost

For strict concentricity casting parts, the products same axle should locate in one cavity whatever female cavity or male cavity. Meet precision request at same time highest possible reduce secondly machining cost.

Aluminium casting company began to produce die cast mold according to the drawings provided by the customer, and through the perfect mold design, our aluminum alloy die casting can better reduce the cost of burrs.

Goalsure is one of the aluminium die casting manufacturers, with complete aluminum alloy casting equipment, and we could do aluminum casting mold making according to drawing,